氮化硅除气转子转轴

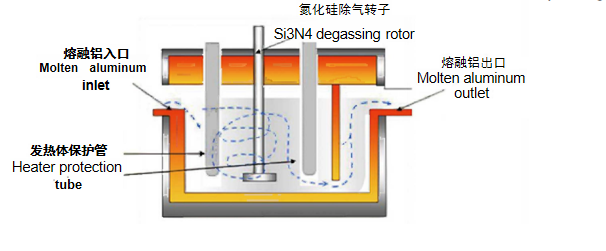

在熔融铝净化过程中,为去除铝液中的氢气,使用氮化硅轴送入氮气或氩气。

高速旋转的转子把进入铝熔体的气体打散形成很多小气泡,

同时促使铝熔体内的氢、夹渣物与气泡接触并随气泡上升而被带出熔体表面,使熔体得以净化。

During the purification process of molten aluminum,to remove hydrogen gas from the molten aluminum,

nitrogen or argon gas is fed through the silicon nitride shaft.

The high-speed rotating rotor and shaft disperses the gas and forms many small bubbles.

The hydrogen and slag inclusions in the molten aluminum are carried out of the melt surface as the bubbles rise.

o 高密度和高强度确保其高速旋转时运行可靠、稳定

o 高耐热冲击性能允许转轴在分批操作时反复从熔融铝中插入和拔出

o 与石墨不同的是,氮化硅升温时几乎不会被氧气腐蚀,这就使其操作寿命更长

o High density and high strength assure the reliable and stable operation during high-speed rotation.

o High thermal shock resistance allows the shaft to be repeatedly inserted and extracted from molten

aluminum during batch operation.

o Unlike graphite,silicon nitride is hardly eroded by oxygen at elevated temperatures,which prolongs